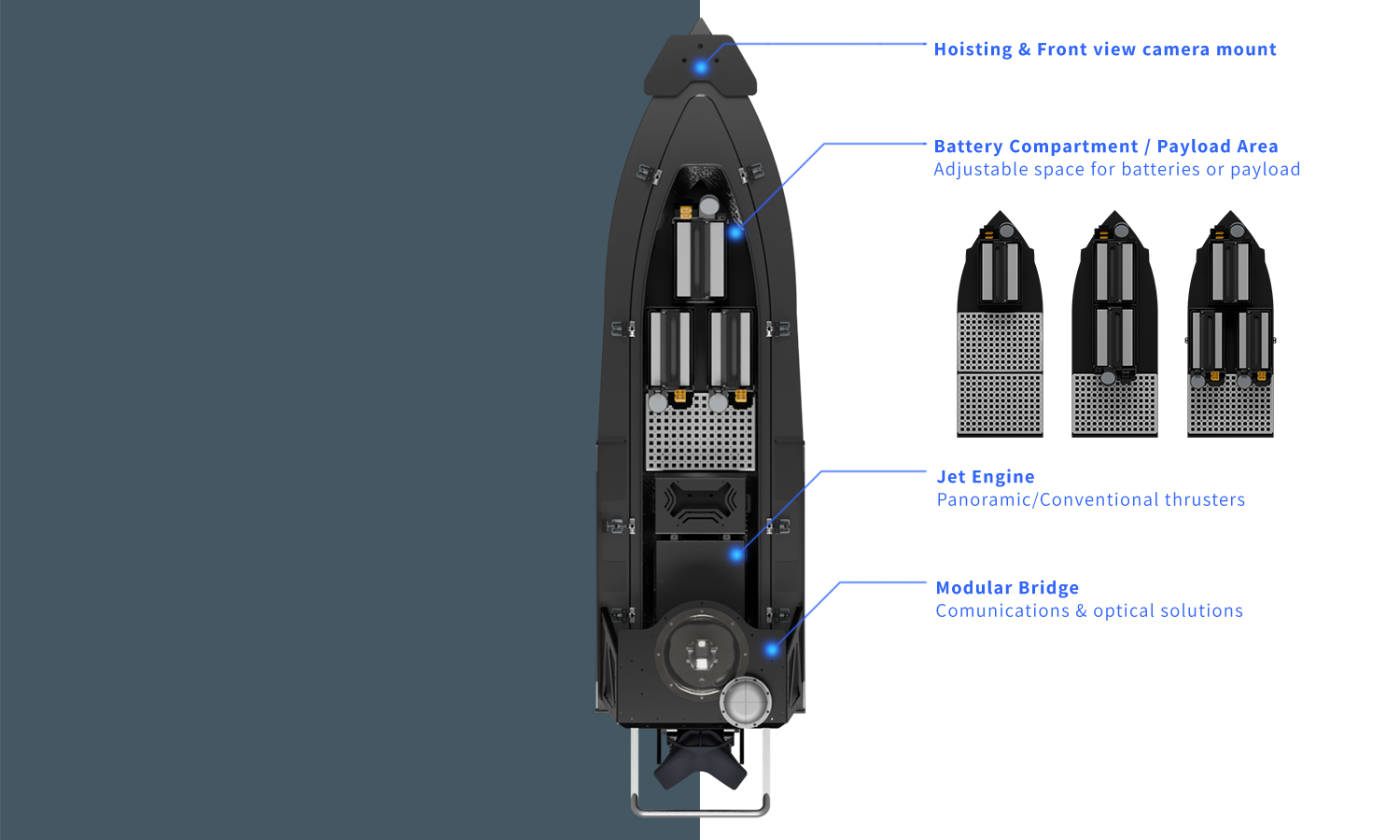

Maven 200

Remotely / Autonomously Operated Tactical USV

Specifications

Specifications

Top Speed

~10/23 Kts

Endurance

~44/87h

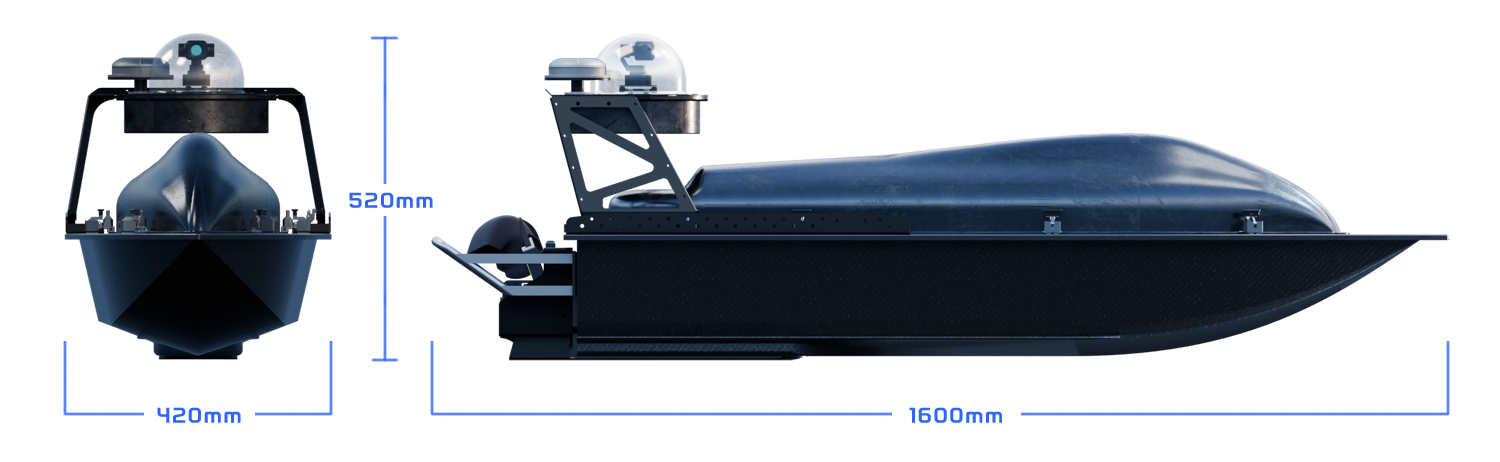

Dimensions

~2100 x 1070 x 800 mm

Payload Weight Capacity

~60kg

Hull Material

Carbon Fiber

Dry Weight

~55kg

Geometry

Composite Hull & Chassis

The Maven 210’s structure is engineered for strength, durability, and efficiency. Dual carbon-fiber hulls joined by precision aluminum beams provide exceptional rigidity while minimizing weight. All flat panels are constructed from reinforced honeycomb-core composites, ensuring an optimal strength-to-weight ratio and corrosion resistance.

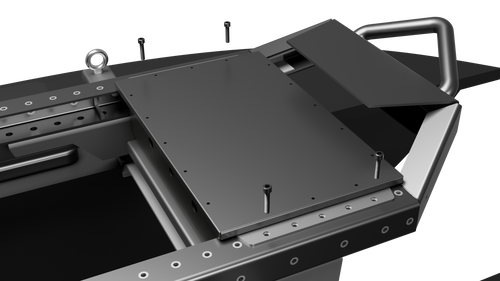

Connecting Rail & Beam

The Maven 210 is built on a fully modular Connecting Rail & Beam system that enables effortless mission reconfiguration. Payloads, electronics, and add-ons can be mounted, replaced, or repositioned anywhere along the rails, maintaining balance and watertight integrity. Front and rear mounting areas provide dedicated points for cameras, sensors, or navigation lights, allowing both forward-view and under-deck installations for complete situational awareness.

Lift & Towing

Safety and operational simplicity are central to the Maven’s handling design. Four integrated lifting points and two towing hooks are positioned directly on the structural beam system for maximum strength. The vessel can be hoisted by crane, towed by another vessel, or used to tow external payloads. An optional crane adapter allows single-point lifting precisely at the center of gravity for safe and balanced operations.

Hoisting and carrying

Shock-absorbing docking station for storage and servicing. Protective “V shape” lift handle shields jet drives and mates to chassis supports for safe hoisting. Flip-over Hatches enable automatic self righting. Anchoring points for hoist and lift at bow/stern. Mobile crate with waterproof wheels available.

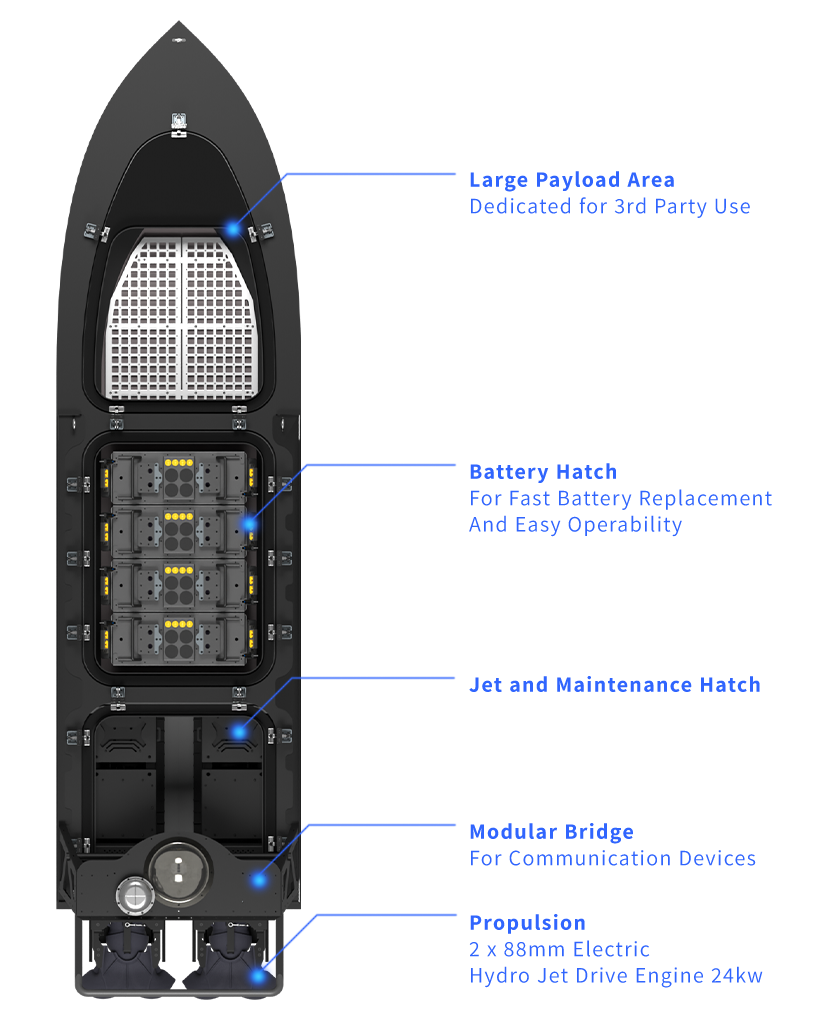

Propulsion

Twin hydro jet drive engines (24 kW). Stainless rock grates and reverse buckets for maneuverability and debris protection; waterproof high-torque servos for steering and reverse actuation.

Electronics & Autonomy

The Maven 210 supports a complete autonomy and control ecosystem. Up to four IP68-rated electronics boxes with several available configuration can be positioned anywhere along the rails for flexible configuration. Each enclosure includes an installation matrix for controllers, power systems, and third-party modules. Optional autonomy packages include Cube Orange+ flight controller, and a full ArduPilot mission suite. On-board companion computers such as Jetson Nano, Raspberry Pi, or Intel Mini PC allow advanced processing, data logging, and AI-driven autonomy

Bridge Options

The Maven platform offers a range of modular bridges that expand its communication, navigation, and sensor capabilities.

- 2-Floor Bridge

Dual-deck structure with independent electronics boxes, providing installation matrices for cameras, LiDAR, radar, antennas, or navigation lights. Each floor can operate independently as a single-deck bridge or together for high-density missions. - SATCOM & LEO Bridges

Purpose-built bridges for satellite communications systems, compatible with Starlink and other LEO terminals. Available in 10 cm and 30 cm versions, these bridges provide vibration-resistant mounting and easy maintenance access. - Custom Bridges

Multiple bridges can be installed along the rails, and custom configurations are available to meet mission-specific requirements.

X-Rail System

Side-mounted X-Rails with M6 positions at 30 mm spacing for quick configuration of add-ons.

Supported Add-Ons

- Modular Bridges (20 cm), electronics box + camera dome

- Antenna brackets (adjustable height/angle)

- Sonar undercarriage (hull-matched profile)

- Balancing buoys for stability tuning

- GPS housing tower (IP-rated routing

Power & Energy

Battery options: 16 Ah and 22 Ah 6S Li Po arrangeable in multiple configurations depending on power or storage needs.

Open design of battery cases to maximize light weight aspects with voltage display; parallel charging up to 8 batteries.

Rollover Configuration & Stability

Our vessels are engineered with a self-righting rollover configuration that ensures maximum reliability and safety in demanding marine conditions. This system combines hull geometry, hatch form, and balance buoys to guarantee that the platform automatically returns to an upright position after capsizing.

Hatch Form Geometry

The hatch is designed with a low-drag, asymmetrical shape that naturally guides the vessel back to its upright orientation. Internal compartments remain sealed and protected, preventing water ingress during rollover events.

Balance Buoys

Strategically placed side buoys act as stabilizers, shifting the center of buoyancy This passive balancing system eliminates the need for active mechanisms, reducing complexity and maintenance.

Reliable Performance

Automatic self-righting capability increases mission survivability in rough seas. Tested for both unmanned and autonomous operations, minimizing downtime and operational risks. Works seamlessly with modular deck rails and bridges, preserving flexibility for add ons.