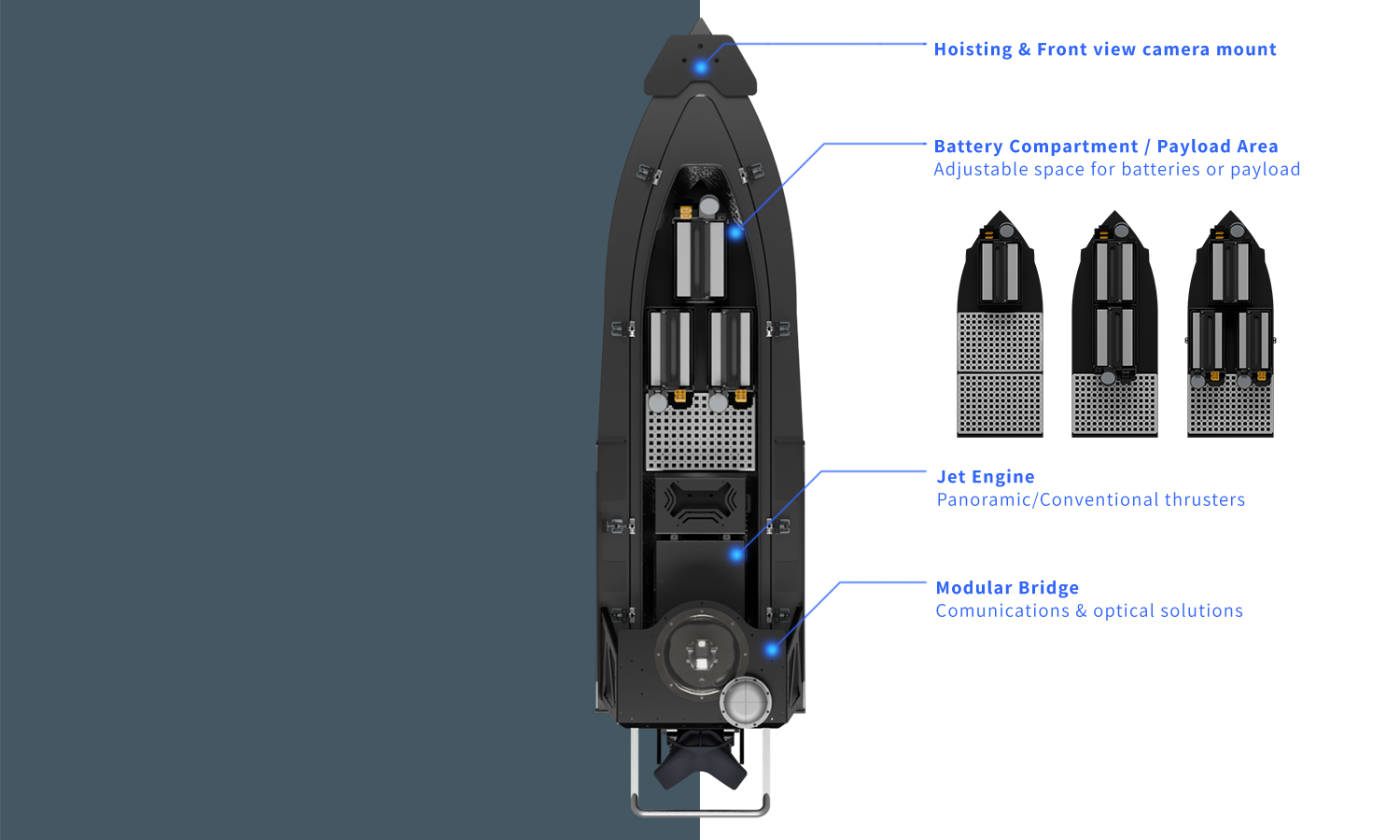

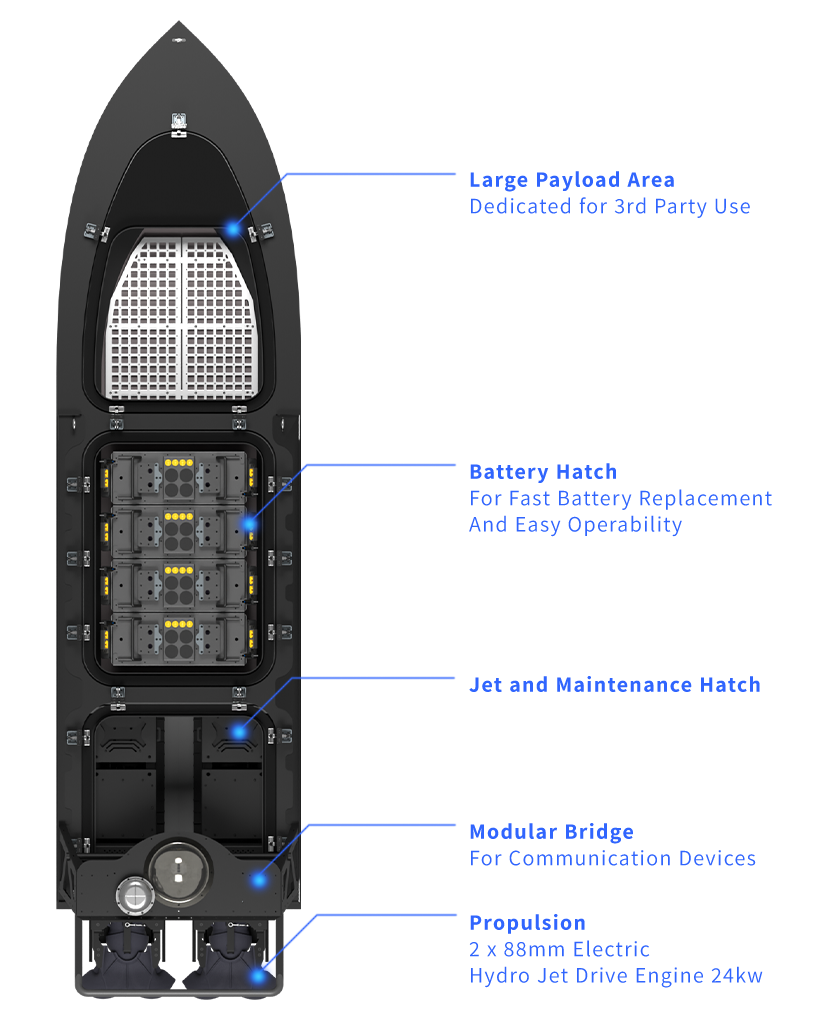

Viper 160

Remotely Operated Tactical Survey USV

Specifications

Specifications

Top Speed

~20/30 Kts

Endurance

~22-52h

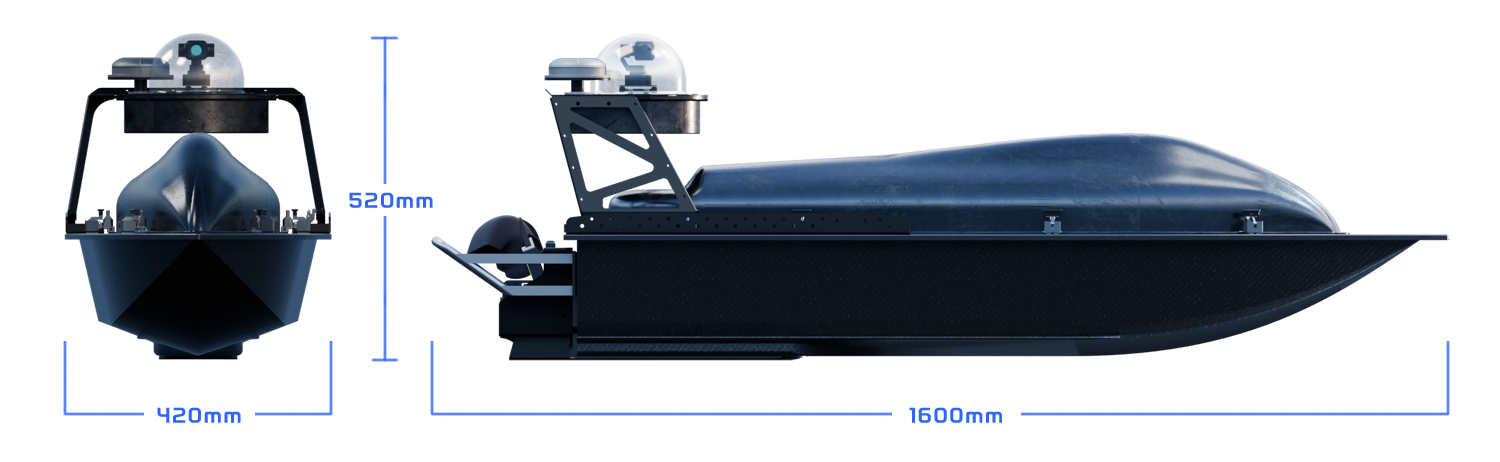

Dimensions

~1600 x 420 x 520 mm

Top/Hull Payload Capacity

~10kg + 4kg

Hull Material

Carbon Fiber

Dry Weight

~17kg

Geometry

Performance

Compact, lightweight platform for rapid deployment and shallow water agility, while efficient power architecture supports day-long operations. Operational up to sea state 4 with recovery safeguards.

Propulsion

A 12 kW Hydro jet drive balances thrust with efficiency for survey speeds. stainless rock grates and reverse buckets for maneuverability and debris protection; waterproof high torque servos for steering and reverse actuation

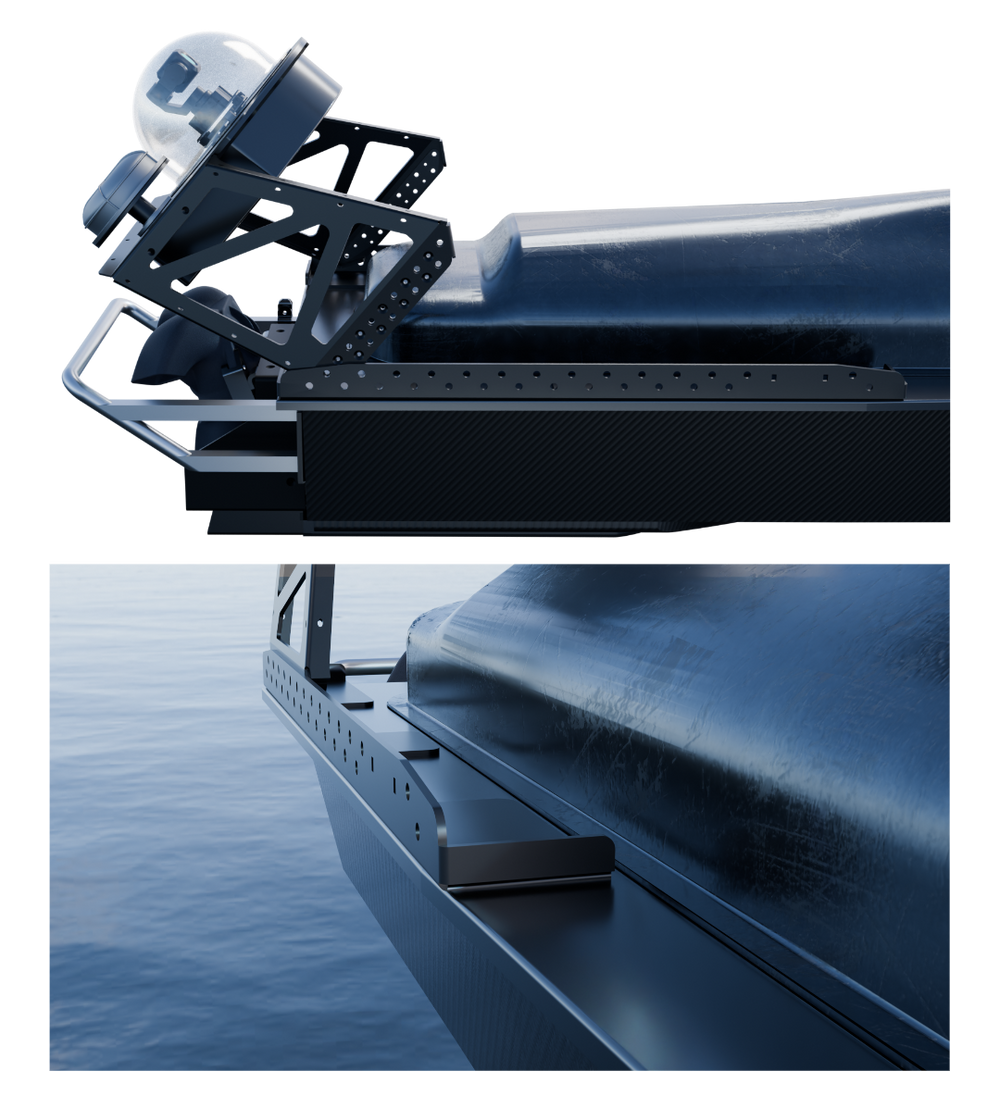

Composite Materials

100% Carbon-fiber materials

Our platforms use advanced carbon-fiber composites, ensuring maximum strength while remaining lightweight. Each vessel includes sealed internal compartments for safety, serviceability, and redundancy.

Our hulls feature a reinforced frame with integrated aluminum components — providing enhanced rigidity and long-term structural durability.

Modular Design

The modular structure is designed around a rail-based mounting framework, allowing quick integration of sensors, payloads, and mission-specific equipment without compromising rigidity.

Key Features:

• Rails System: Continuous rails across the deck provide flexible mounting options.

• Bridges: Multiple bridges can be installed along the rails at any position, creating structural support points for

electronics, antennas, or payload housings.

• Rapid Reconfiguration: Reassign or relocate modules along the rails for different missions (bathymetric mapping, security, environmental monitoring, etc.).

Autonomy & Control

- Autonomy: Flight controller + GPS (Pixhawk/Cube Orange+, Mission Planner/QGC)

- Handheld RC: 2.4 GHz (FrSky X-Lite Pro) basic telemetry (1–4 km variants)

- Mobile HD GCS: HereLink / Skydroid H16/H30 / SIYI

MK32 (up to ~50 km with directional antenna) - Backhaul: Dual-SIM modem options (RUT-956 / Archer MR600)

- Onboard compute: Raspberry Pi / Jetson / i5 Mini PC

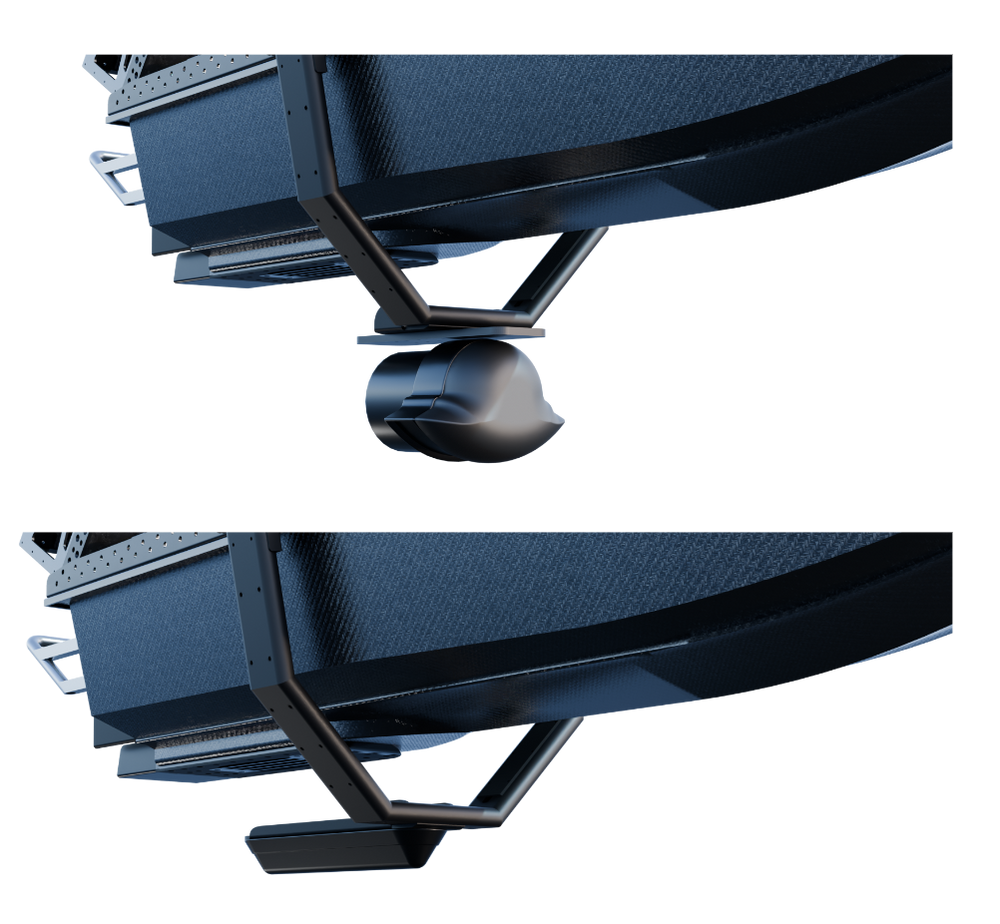

Submersible Brackets

The modular structure is designed around a rail-based mounting framework, allowing quick integration of sensors, payloads, and mission-specific equipment without compromising rigidity.

Key Capabilities:

• Sonar Systems:

- Side-scan and multibeam sonars for high-resolution seabed mapping

- Real-time imaging for navigation and obstacle detection

- Depth profiling to support bathymetric and hydrographic surveys

• Environmental Sensors:

- Water quality probes for measuring water quality

- Pollution detection modules for identifying oil spills, chemical leaks, or harmful algae

X-Rail System

Side-mounted X-Rails with M6 positions at 30 mm spacing for quick configuration of add-ons.

Supported Add-Ons

- Modular Bridges (20 cm), electronics box + camera dome

- Antenna brackets (adjustable height/angle)

- Sonar undercarriage (hull-matched profile)

- Balancing buoys for stability tuning

- GPS housing tower (IP-rated routing

Docking & Handling

Our vessels are designed for safe, simple, and reliable docking and handling, even in demanding environments. Every detail of the system is built to reduce operator effort, protect critical components, and ensure mission readiness.

- Protective Lift Handle

A specially engineered handle shields the jet drive and doubles as a robust support point for hoisting and lifting, ensuring both safety and convenience. - Integrated Lift Rope

A reinforced rope system designed for secure, ergonomic lifting by hand, providing operators with a simple and reliable way to carry and maneuver the vessel during launch, recovery, or ground transport. - Mobile Transport Solutions

Vessels can be moved using a custom crate, making it easy to transport across rough terrain or between deployment sites.

Hoisting and carrying

Shock-absorbing docking station for storage and servicing. Protective “V shape” lift handle shields jet drives and mates to chassis supports for safe hoisting. Flip-over Hatches enable automatic self righting. Anchoring points for hoist and lift at bow/stern. Mobile crate with waterproof wheels available.

Power & Energy

Battery options: 16 Ah and 22 Ah 6S Li Po arrangeable in multiple configurations depending on power or storage needs.

Open design of battery cases to maximize light weight aspects with voltage display; parallel charging up to 8 batteries.

Rollover Configuration & Stability

Our vessels are engineered with a self-righting rollover configuration that ensures maximum reliability and safety in demanding marine conditions. This system combines hull geometry, hatch form, and balance buoys to guarantee that the platform automatically returns to an upright position after capsizing.

Hatch Form Geometry

The hatch is designed with a low-drag, asymmetrical shape that naturally guides the vessel back to its upright orientation. Internal compartments remain sealed and protected, preventing water ingress during rollover events.

Balance Buoys

Strategically placed side buoys act as stabilizers, shifting the center of buoyancy This passive balancing system eliminates the need for active mechanisms, reducing complexity and maintenance.

Reliable Performance

Automatic self-righting capability increases mission survivability in rough seas. Tested for both unmanned and autonomous operations, minimizing downtime and operational risks. Works seamlessly with modular deck rails and bridges, preserving flexibility for add ons.